NEWS

Giant Gantry Machining Center Nears Completion, Set for Shipment by Nengwei Tech

**Giant Gantry Machining Center Nears Completion, Set for Shipment by Nengwei Tech**

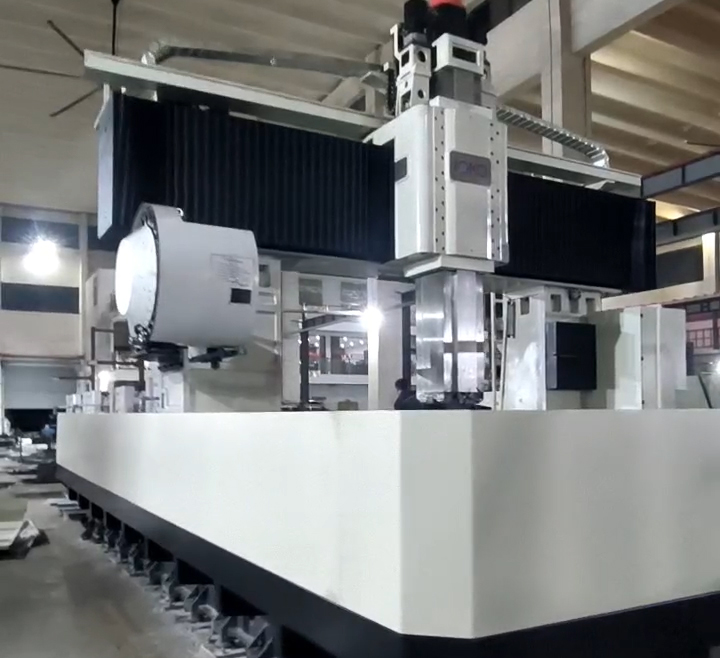

**Taizhou, China, [Date]** – Nengwei Technology Co., Ltd., a frontrunner in advanced intelligent manufacturing solutions, today announced that its most ambitious engineering project to date, the colossal **NW-GMC3200 Heavy-Duty Five-Axis Gantry Machining Center**, is entering its final commissioning phase and is scheduled for shipment to a leading global aerospace manufacturer by the end of this quarter. This milestone underscores Nengwei Tech's capability to design and deliver world-class, large-scale precision equipment that meets the stringent demands of high-tech industries.

The **NW-GMC4080** is engineered to redefine the manufacturing of ultra-large, complex components. With an impressive working envelope of **12 meters in length, 5 meters in width, and 4 meters in height**, and a load-bearing capacity exceeding 50 tons, it is set to become a cornerstone in the production of critical parts for aerospace frames, large-scale industrial molds, renewable energy equipment (such as wind turbine hubs and frames), and next-generation transportation infrastructure.

"The imminent completion of the NW-GMC4060 is a proud moment for every engineer and technician at Nengwei Tech," stated Mr. Li Qiang, CEO of Nengwei Technology. "This machine embodies our corporate philosophy of ‘Engineering Precision, Empowering Industry.’ It is not merely a piece of equipment; it is a turnkey solution that will enable our client to tackle projects previously considered unfeasible, significantly compressing their development cycles and enhancing their competitive edge on the global stage."

**The NW-GMC3200 incorporates Nengwei Tech's latest proprietary innovations, featuring:**

* **Uncompromising Structural Integrity:** The machine utilizes a unique, optimized ribbed structure made from high-grade, polymer-concrete composite and thermally-symmetrical cast iron. This design ensures exceptional static and dynamic stiffness, superior vibration damping (over 3 times better than conventional steel), and unparalleled thermal stability, guaranteeing consistent micron-level accuracy (< 0.008mm) over extended, heavy-duty machining cycles.

* **Breakthrough Five-Axis Performance:** Equipped with Nengwei's proprietary **"SynchroTilt-5X"** milling head and a massive, direct-drive dual-pallet rotary table, the center offers full five-axis simultaneous machining with exceptional torque and precision. This allows for the complete finishing of complex contoured parts in a single setup, eliminating cumulative errors and saving hundreds of hours in re-fixturing.

* **High-Efficiency Intelligent Machining:** A powerful 60,000 Nm spindle motor, coupled with Nengwei's **"SmartFeed"** adaptive control system, allows for aggressive machining of difficult materials like titanium alloys and composites. The system intelligently adjusts feed rates and cutting parameters in real-time based on spindle load, optimizing material removal rates while protecting the tool and workpiece.

* **Fully Integrated Digital Ecosystem:** The NW-GMC3200 is at the heart of Nengwei's **"iMachining 4.0"** platform. Fitted with a comprehensive network of sensors, it enables real-time monitoring of machine health, predictive maintenance alerts, remote diagnostics, and seamless data integration into the client's factory management systems for truly digitalized production.

Currently, the machine is undergoing a rigorous final validation protocol in Nengwei Tech's state-of-the-art testing facility. This includes laser calibration, dynamic accuracy verification using a telescoping ballbar, and a comprehensive 120-hour continuous cutting trial on a full-scale aerospace component prototype to certify all performance metrics.

The successful delivery and commissioning of the NW-GMC3200 will mark a significant leap forward for both Nengwei Tech and its client, enabling the manufacture of next-generation products with higher complexity, better quality, and lower total cost. It solidifies Nengwei Tech's position as a strategic partner capable of providing innovative, heavy-duty machining solutions that drive industrial advancement.

**About Nengwei Technology Co., Ltd.:**

Nengwei Technology is a high-tech enterprise specializing in the R&D, manufacturing, and service of high-end, intelligent CNC machine tools and automated manufacturing lines. With a focus on technological innovation and customer-centric solutions, Nengwei Tech serves global leaders in aerospace, automotive, energy, and precision engineering, committed to empowering the future of smart manufacturing.