PRODUCTS

JN-D10 Eight-spindle Precision Carving Machine

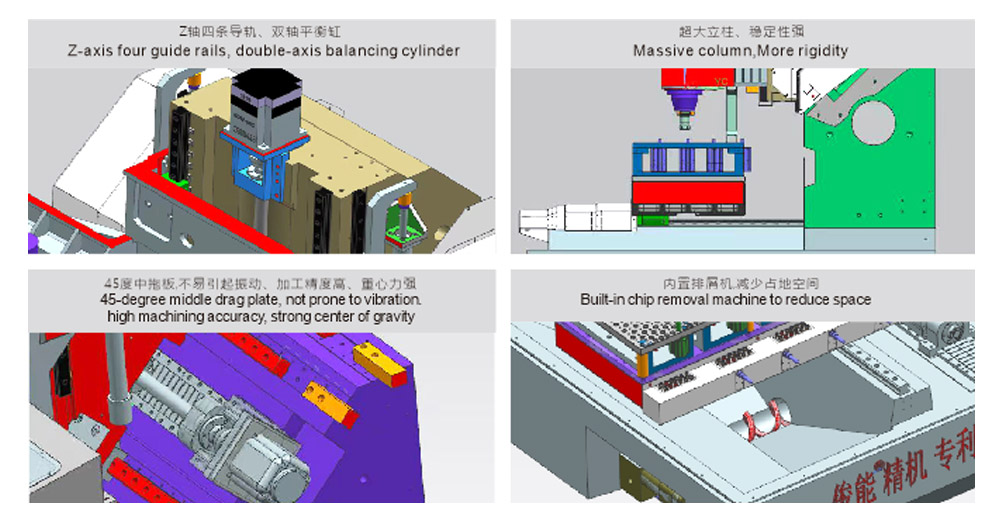

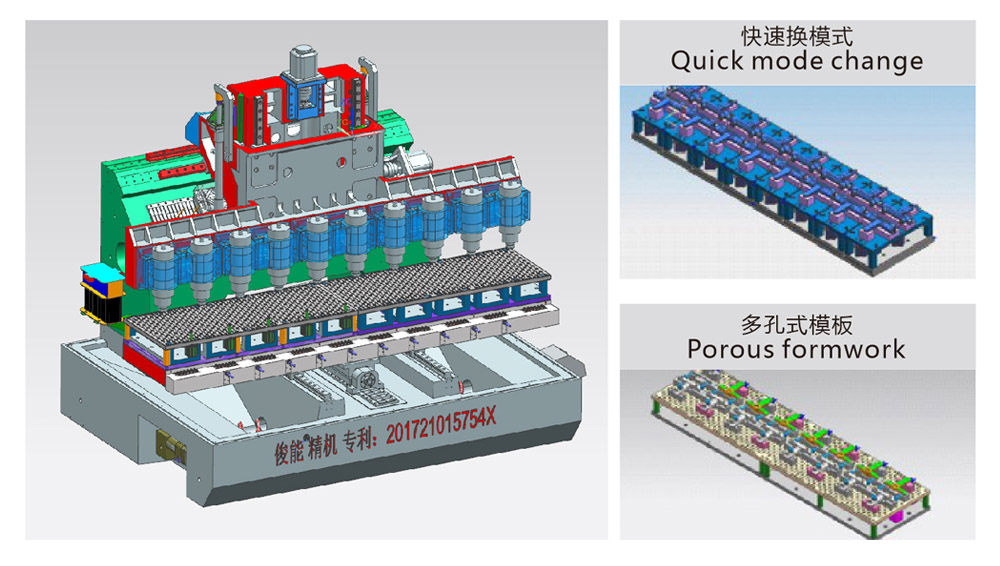

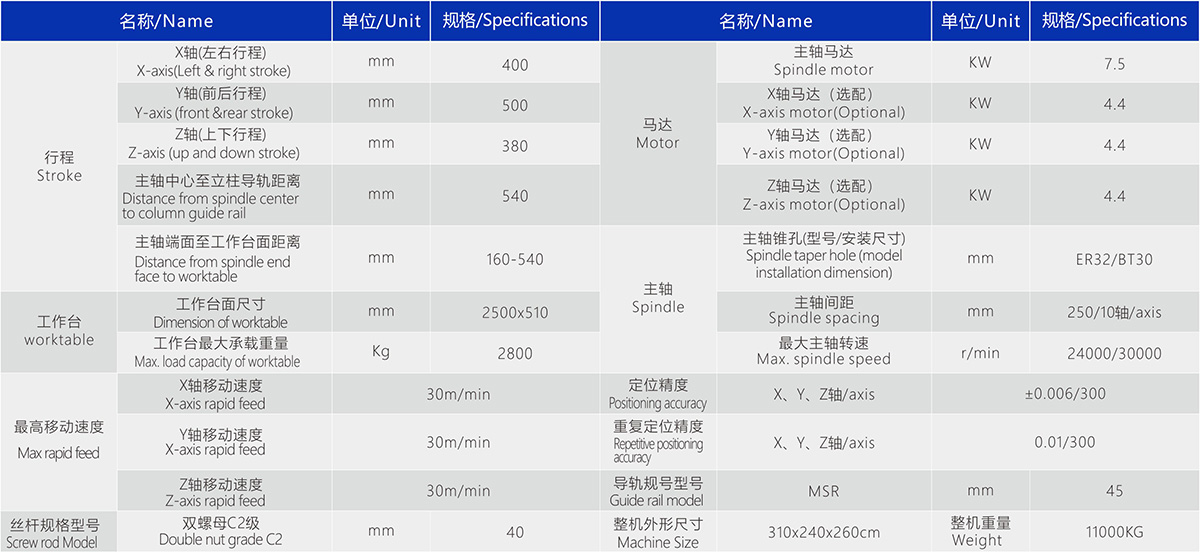

Machine JN-D10 is equipped with SYNTEC system as standard. Users can choose SIEMENS or MITSUBISHI syetem.The new generation model optimizes the acceleration characteristics of each axis to achieve high-speed, high-precision and high-quality surface processing.It adopts roller guide rail to effectively control the stability and rigidity of the machine tool.The machine adopts marble mineral casting body which is efficient,stable,and non-deformable.At present it is the first large-scale mineral casting precision carving equipment in the domestic and oversea markets.

①The safety light curtain and double-button start more effectively protect the safety of life and property.

②The fixture manually clamps the detection device to prevent the unclamped product from starting the program, protect tool life and reduces

Starting the product obsolete rate.

③ Double-valve switch clamping device to prevent the operator's fingers from being pinched during working.

④ The sealing strip has been installed at the connection of the outer sheet metal of the machine tool, which has a good effect on waterproof and sound insulation, and improves the grade of the production workshop.

Detailed introduction