PRODUCTS

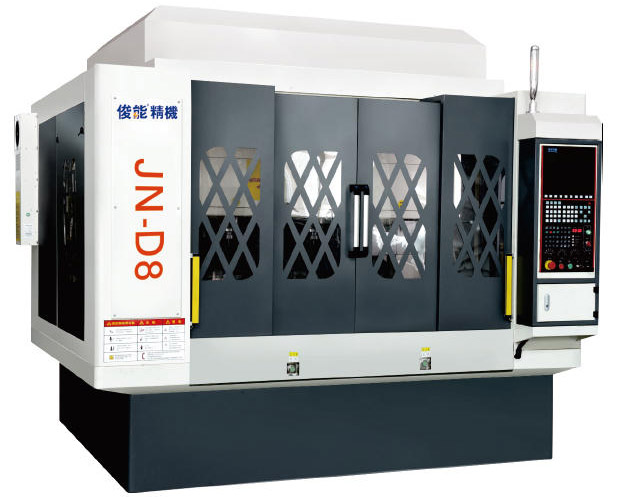

JN-D8 Eight-spindle Precision Carving Machine

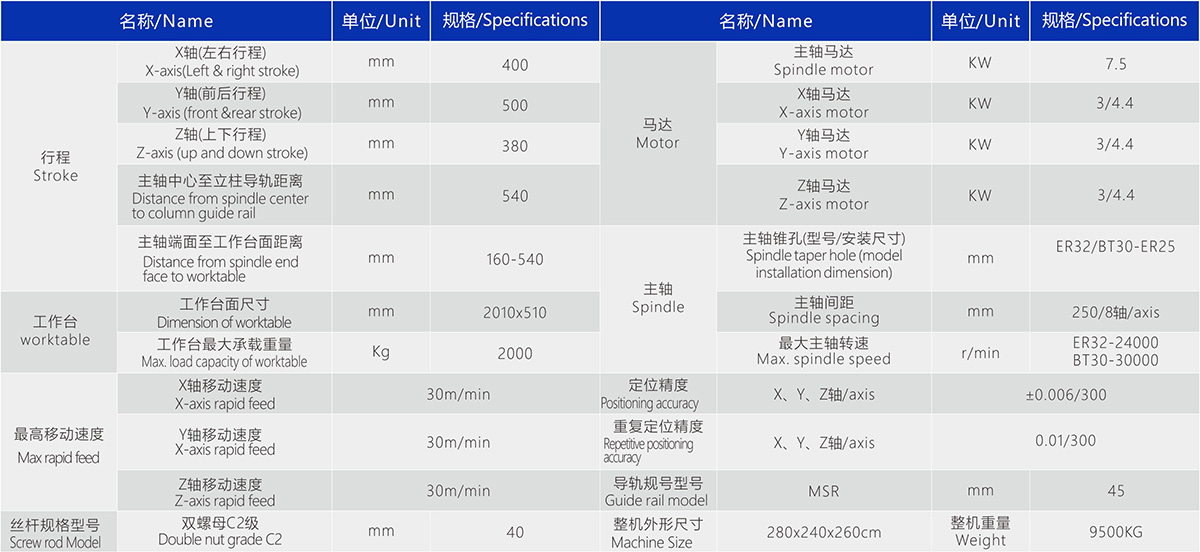

Machien JN-D8 is equipped with SYNTEC system as standard. Users can choose SIEMENS or MITSUBISHI system.The new generation modeloptimizes the acceleration characteristics of each axis to achieve high-speed,high-precision and high-quality surface processing.It adopts rollerguide rail to effectively control the stability and rigidity of the machine tool.The machine adopts marble mineral casting body which isefficient,stable,and non-deformable.At present it is the first large-scale mineral casting precision carving equipment in the domestic and overseamarkets.

① The safety light curtain and double-button start can more effectively protect the safety of life and property.

② The fixture manually clamps the detection device to prevent the unclamped product from starting the program, more effectively protect the toolservice life and reduce the product scrap rate.

③Double-valve switch clamping device to prevent the operator's fingers from being pinched during working. The sealing strip has been installed atthe connection of the outer sheet metal of the machine tool, which has a good effect on waterproof and sound insulation, and improves the gradeof the production workshop.

④The sealing strip has been installed at the connection of the outer sheet metal of the machine tool, which has a good effect on waterproof andsound insulation, and improves the grade of the production workshop.

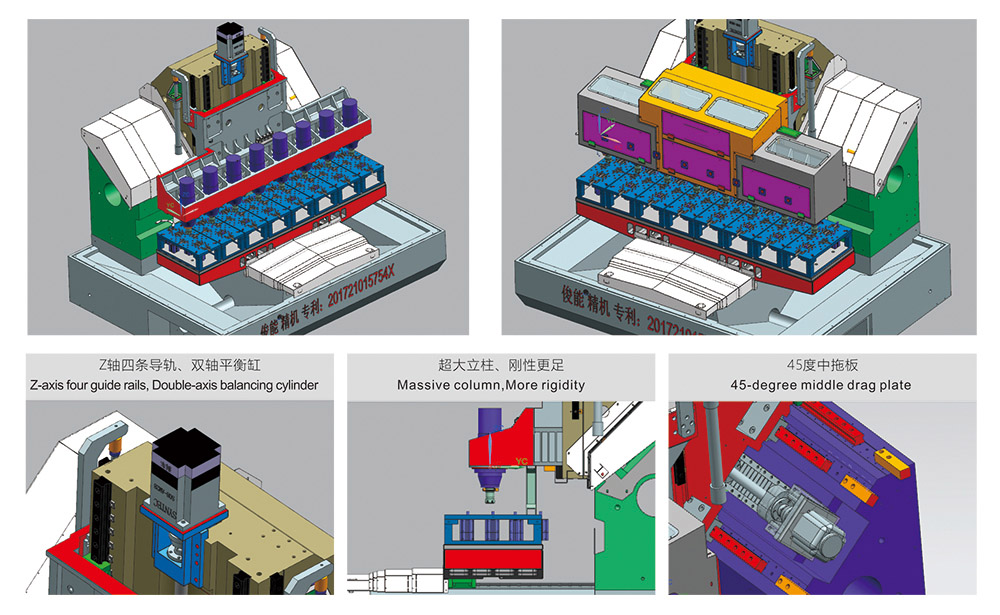

Detailed introduction