PRODUCTS

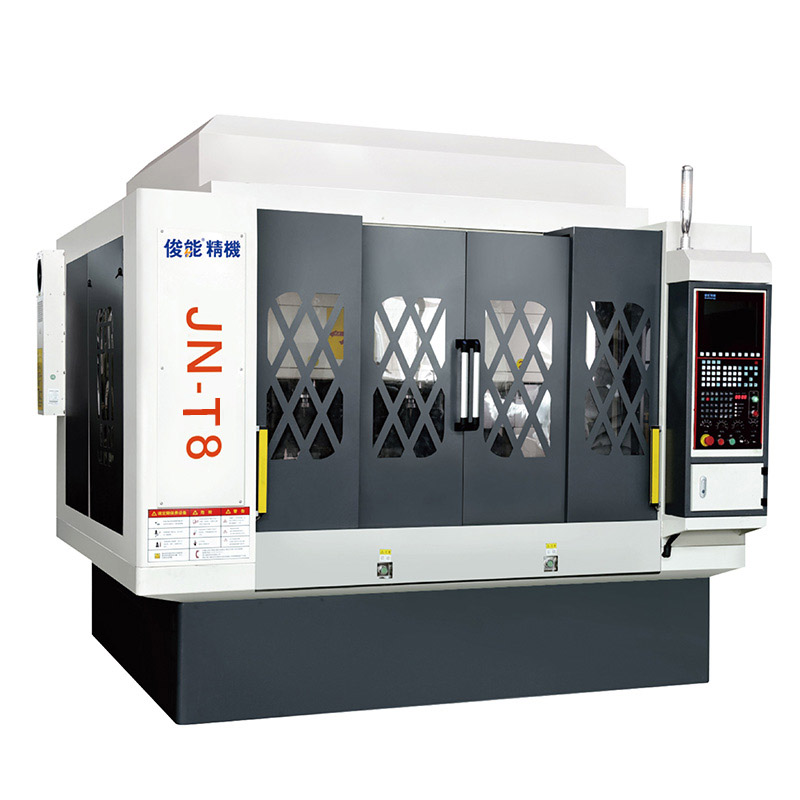

JN-T8 Eight-Axis Precision Engraving Machine

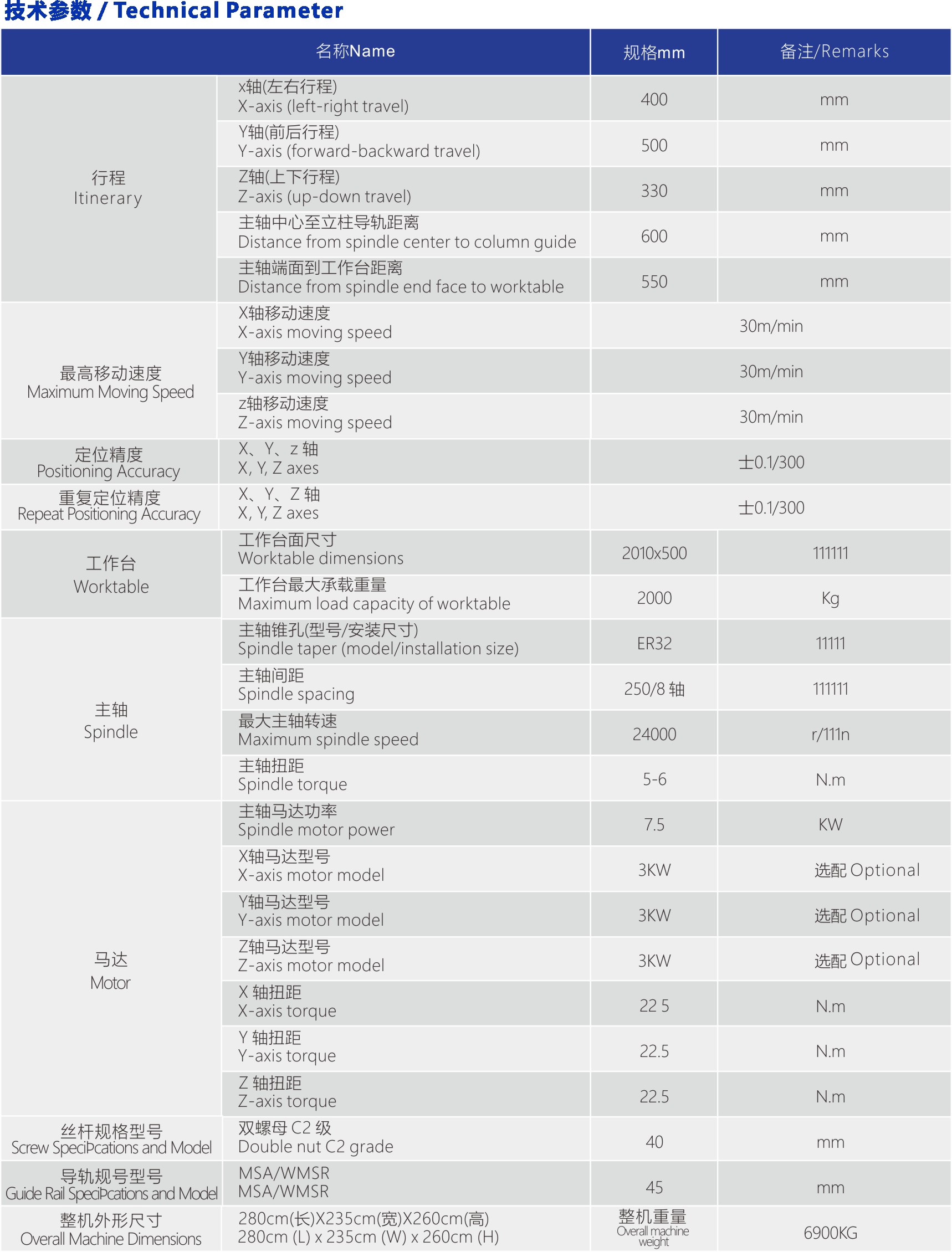

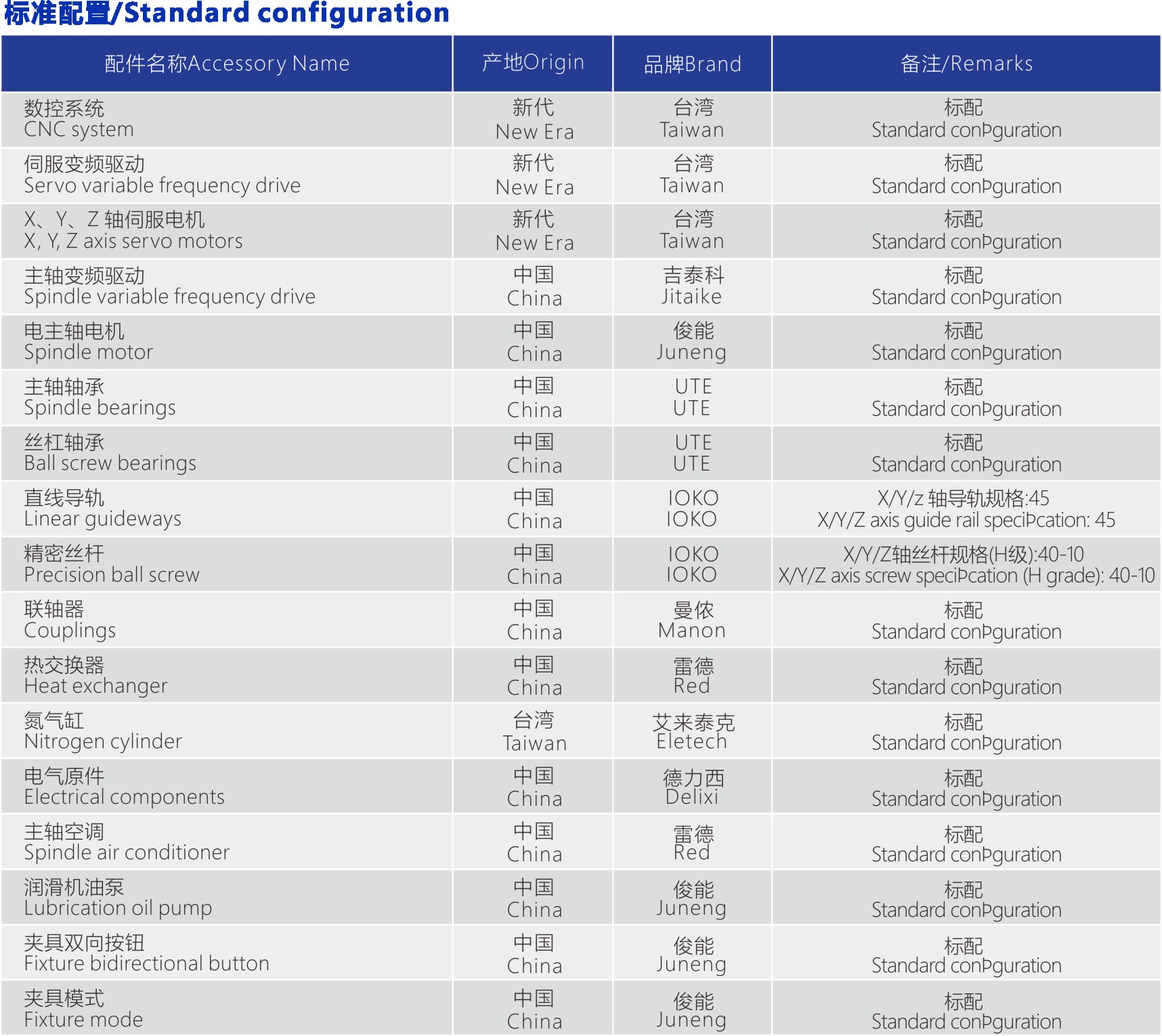

1. The JN-T8 uses three double-sided 45-type ball guides; machining is more stable, and processing efficiency is higher.

2. The JN-T8 machine has a small footprint, a large effective travel, high spindle speed, and a heavy machine body.

3. The JN-T8 features dual-axis ammonia balance cylinders, which more effectively protect the lead screw and motor.

4. The JN-T8 adopts internal chip removal, saving more space.

5. The JN-T8’s three-axis motor has a maximum linear speed of 30 m/min, 30% higher processing efficiency than similar machines.

6. The engraving machine has obtained a national patent, patent number ZL 201822108753.0.

7. The JN-T8 engraving machine has a unique appearance and elegant design.

8. Comparing gantry engraving machines with column-type engraving machines: column-type machine heads are prone to deformation, have slower processing speeds, and instability, leading to rough product surfaces. Gantry machine heads are less prone to deformation (center of gravity advantage), process faster, and produce smoother surfaces.

9. The JN-T8 engraving machine is the first in the country to adopt a constant-temperature detection protection device, monitoring spindle temperature in real-time to prevent spindle overheating and seizure, more effectively protecting the spindle's service life.

Detailed introduction